Hypervelocity Impact Testing on Simulated Lunar Materials

Specialised Imaging reports on how the Institute of Astronautics, Technical University of Munich, Germany has used a SIM-X ultra-high speed framing camera to record high resolution images of hypervelocity impacts on granular media samples with different bulk densities.

At the Institute of Astronautics, research to investigate principles for lunar in-situ resource utilization (ISRU) has been conducted. Lunar regolith provides a multitude of elements which are bound in ores and minerals. The thermal, chemical and mechanical properties, may change significantly upon the high pressures of a hypervelocity impact. To simulate this process, impact tests were carried out using 25mg Polyethylene or 73mg Aluminium cyliders fired at 1-4 Km/sec at lunar granular material simulant (JSC-1A) under vacuum conditions. Through undertaking these experiments the researchers sought to measure the velocity and angle of materials ejected as a result of hypervelocity impact to see if the ejecta might be lost from the lunar surface into space.

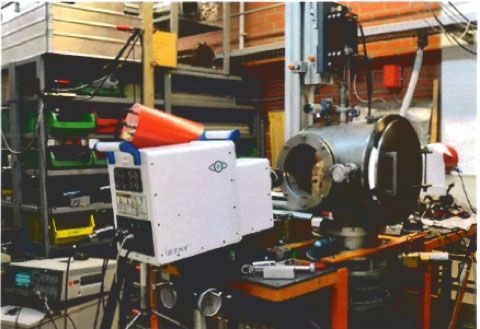

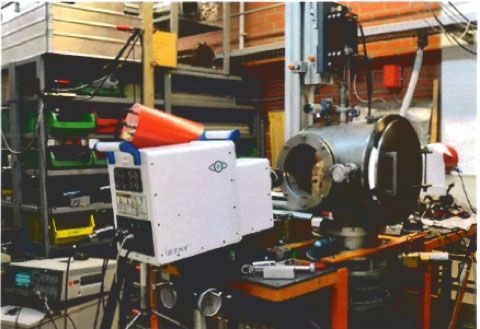

The main diagnostic tool used for the impact experiments was a Specialised Imaging SIM-X ultra-high speed framing camera. The camera features up to 16 discrete intensified optical channels with an image size of 1360 x 1024 pixels at 12-bit resolution. Each frame can be programmed individually concerning gain and exposure to optimise data capture. With a minimum interframe tome of just 5 ns the SIM-X can capture high quality images to help unlock the secrets of even the most fleeting pof events. The illumination of the simulated lunar surface impact event was realised using two high power flash heads with a total light duration of about 4ms.

Dr M Rott, a researcher at the Institute of Astronautics commented “The SIM-X camera has proven to be a powerful diagnostic tool enabling us to gain much insight into the formation and development of ejecta clouds resulting from hypervelocity impacts on simulated lunar materials. The good time resolution of the camera recordings revealed previously unknown facts for instance that under some conditions the SWIP can rebound from the surface with a substantial velocity”. Dr Rott added “We would like to thank Specialised Imaging for their valuable help in setting up the camera”.

A paper describing these experiments in full entitled ‘Impacts on Regolith and Granular Media’ by M.Rott and P.Hager is available on request from Specialised Imaging on +44-1442-827728 / +49-8141-666-8950 / +1-951-296-6406 or info@specialised-imaging.com.

For further information on the SIM-X ultra-high speed framing camera please visit www.specialised-imaging.com.

The Institute of Astronautics at the Technical University of Munich (www.lrt.mw.tum.de) analyses, investigates and develops advanced space flight concepts and technologies.

The focus of its Real Time Teleoperation research group is set on simulation and evaluation of mission concepts and technologies for robotic applications in Earth orbit.

The focus of its Exploration Tchnologies research group is on numeric simulations and laboratory experiments regarding safe and reliable technologies for long-term manned space exploration. In order to be able to understand and handle typically complex space systems, the Systems Engineering research group investigates novel methods of model-based design.

Specialised Imaging is a knowledgeable, dynamic company focused upon design, manufacture, service and supply of ultra high-speed imaging systems and components for industrial, defence and scientific applications. The company's continuing policy is to invest in the development of innovative imaging solutions, incorporate the latest technological advances and use improved components wherever possible. A total commitment to quality and a thorough understanding of applications are held as the keys to the future.

Image 1:

Set-up of the target chamber with the SIM-X camera (courtesy: Institute of Astronautics, TUM)

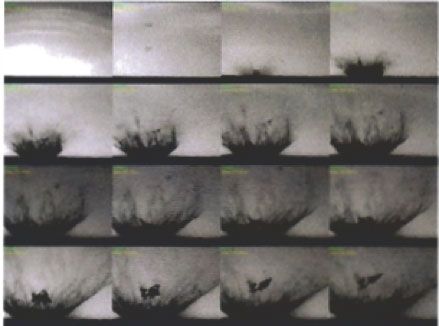

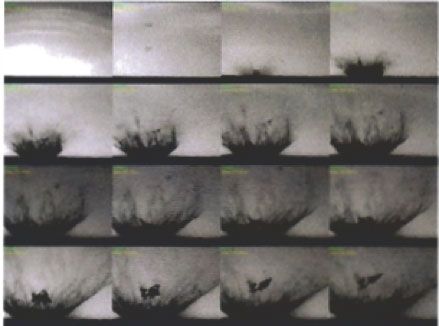

Image 2:

25mg polyethylene impacting high density Regolith (200 microsecond time frame)